Industrial-R8

Industrial Project Management

Atmospheric Distillation Column Conversion to Vacuum Operation

- $7.3 Million Project

- Severe Corrosion Problem Solved

- Vapor Feed for Energy Savings

Designed and Installed by:

W. I. Jackson, BChE,

Founder, WIJ Tech Projects, LLC

Distillation column and auxillary equipment are to be dismantled, removed, and replaced. Area was accessible only by vertical caged ladders. A new 4-story stairwell improved safety, facilitated personnel access to the work area, and shortened turn around time. The man standing in the new stairwell with a fire extinguisher behind him is on fire watch: cutting torches are being used inside the building under a burn permit to free the old column.

Wij Tech Projects, LLC “Let’s Build it Together”

Distillation column and auxillary equipment are to be dismantled, removed, and replaced. Area was accessible only by vertical caged ladders. A new 4-story stairwell improved safety, facilitated personnel access to the work area, and shortened turn around time. The man standing in the new stairwell with a fire extinguisher behind him is on fire watch: cutting torches are being used inside the building under a burn permit to free the old column.

Wij Tech Projects, LLC “Let’s Build it Together”

Distillation column and auxillary equipment are to be dismantled, removed, and replaced. Area was accessible only by vertical caged ladders. A new 4-story stairwell improved safety, facilitated personnel access to the work area, and shortened turn around time. The man standing in the new stairwell with a fire extinguisher behind him is on fire watch: cutting torches are being used inside the building under a burn permit to free the old column.

Distillation column and auxillary equipment are to be dismantled, removed, and replaced. Area was accessible only by vertical caged ladders. A new 4-story stairwell improved safety, facilitated personnel access to the work area, and shortened turn around time. The man standing in the new stairwell with a fire extinguisher behind him is on fire watch: cutting torches are being used inside the building under a burn permit to free the old column.

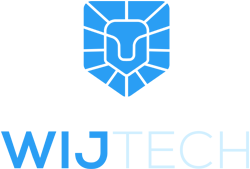

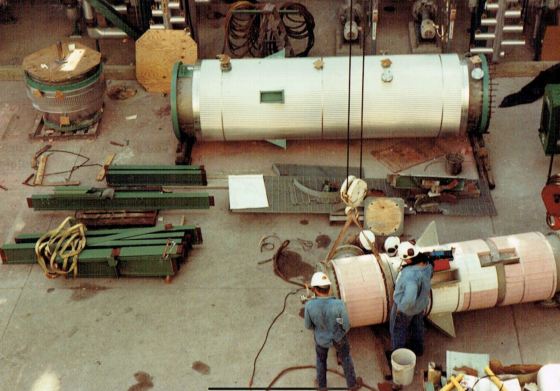

The old column is removed from the building. Left behind are holes in the floor at three levels (red arrow). The new column will operate under vacuum and hence, it must be larger in diameter to maintain the same thru-put. Therefore, the holes in the floors had to be enlarged. Also, the new column weighing more than the old one necessitated modifications to the building’s structural steel.

Top – Old column removed from the building, is on the ground and broken open for inspection. You can see where a series of pre-shutdown ultrasonic thickness measurements were taken (red arrow) which showed that the vessel walls were thinning.

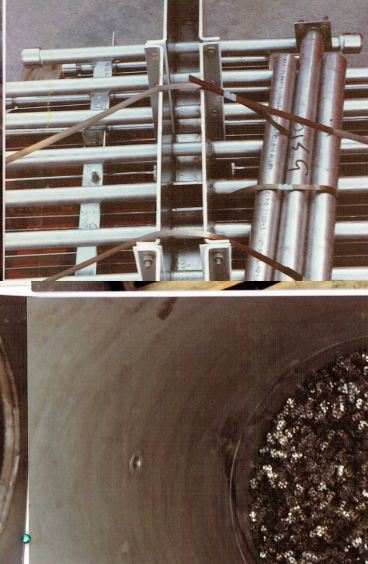

Bottom – Stripping section vapor distribution tray as well as the feed distribution manifold are discolored from severe corrosion as expected.

Stripping section of the old column shows discoloration and severe wall corrosion. Wij Tech’s recommendation for conversion to vacuum distillation with vapor feed significantly reduced bottoms temperature and the corrosion rate, while simoultaneously cutting energy cost. We also recommended internal materials be upgraded from stainless steel.

New liquid reflux distribution manifold with upgraded material can be seen in top photo.

In the bottom picture peering into the new stripping section, you see some of the new corrosion resistant Pall ring packing.

The replacement pieces must be lifted to the top of the four-story building. We consider the object’s weight and the required boom angle in reaching a concensus that we have enough crane capacity to make a lift. Using two 50 ton cranes, we will carefully lower each piece into place through the holes left in the floors from where the old column was removed.

Industrial and Commercial

Areas of Design and Process Expertise

- AIRUSOL™

- Powerhouse Optimization

- Vacuum Distillation

- 3 Phase Azeotropic Distillation

- Heat and Mass Transfer

- Pneumatic Conveying of Solids

Wij Tech Projects, LLC

Let’s Build it Together

***Home of the AIRUSOL™